Almost Maintenance Free Closing Unit

| The traverse castings of the frame have been specifically designed for each type of press to provide excellent rigidity. Deformation of the plates under load is less than 0.10 mm. |  | A pivoting indexing block inserts itself between the moving traverse and the mold adjusting screw. A cylinder incorporated into the fixed traverse opposite the injection unit provides the clamping function. | |

| The floating column frame prevents wear on the moving traverse guide rings.Guiding of the moving parts with self-lubricating bearings reduces both the frequency of maintenance operations and their cost. |  | Engineering parts are designed from the outset to receive options either when ordered or as a retrofit, which means the press can be customized or upgraded at a later time. | |

| Shoulderless columns ensure easy parallelism adjustment.This design greatly extends the life of the equipment, ensures the dimensional quality of the parts and limits flashing on the parts. |

Y type injection units & high technology ----------------------------------------------------------------------------------------

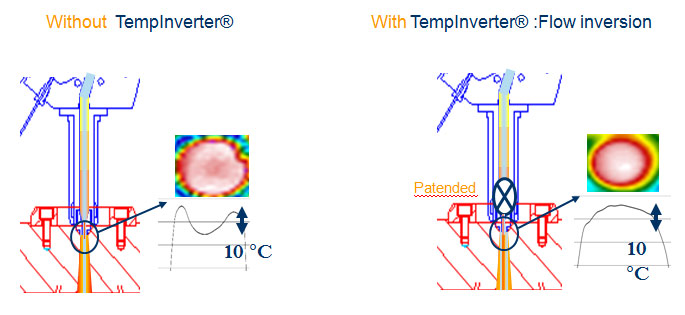

Injection Unit Y type + TempInverter ®

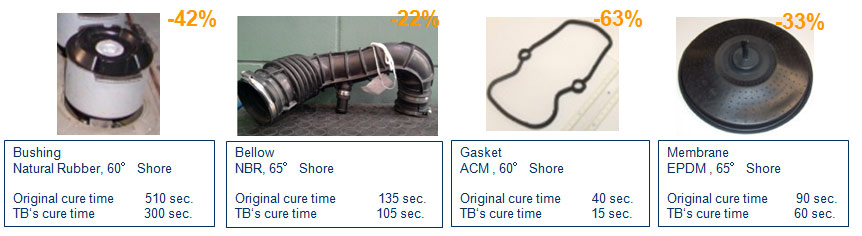

Examples: Cure time reduction with TurboCure® (TempInverter® + FillBalancer®)

Additional Advantages: Reduced scrap rate, less non-fill\ More robust process because of a larger process window; More homogenous parts characteristics\ Less waste: reduced flash and lower runner section; Cleaner parts, so less finishing secondary operations labor\Cleaner mold, so reduced labor for demolding and reduced need for mold cleaning